Power Transformer

ZELECT:Your Professional Power Transformer manufacturer!

Baoding Zhongyi Electric Corporation. Here in short referred to as "ZELECT", located in Baoding city, Hebei province, China. Founded in 2008, our company is one of the "high-tech enterprises", which produce and sell power transformer, high and low voltage switch-gear and prefabricated substations.

24H Online Service

Advanced Equipment

Professional Team

One-Stop Solution

24H Online Service

Your inquiry will be replied within 24 hours.We also provide customized service and the perfect power solution to meet your requirements.

advanced equipment

We have many very advanced and complete production equipment to ensure the excellent quality of our products

professional team

There are currently 260 employees, including 18 technicians who have been engaged in the research and development of transformer products for many years, and 8 high-quality corporate managers.

global shipping

Our sales network is divided to five main regions: America, Southeast Asia, West&South Asia, Europe&Africa, Russian Market.

A power transformer is defined as a transformer that operates with high voltages and currents in the power system network. It is mainly used to increase or decrease the voltage level between the generator and the distribution circuits. A power transformer has two or more winding that are magnetically coupled through a core. A varying current in one winding creates a varying magnetic flux in the core, which induces a varying voltage in the other winding. The ratio of the voltages in the primary and secondary winding depends on the number of turns in each winding.

Power transformers are classified as static devices because they have no moving or rotating parts. They are also passive devices because they do not generate or consume electrical energy, but only transfer it from one circuit to another. Power transformers can operate with high efficiency and reliability for long periods of time.

Features of Power Transformer:

Amount of Local Discharged

The apparent discharge amount is less than 80pC at 1.5 times the rated voltage;

Noise

Products of 63MVA and below are lower than 58dB (AN);

Power loss

No-load loss is 30% lower than that of IEC standard;

Reliability

All products in use are free from damage or oil leakage;

Customization

Transformers can be customized according to your requirements;

Short delivery time

Competitive short delivery times.

What are Advantages of Power Transformer?

Energy-Saving Effect:

Our power transformer has the characteristics of low no-load loss and low load loss.

Transformer Core:

The iron core adopts a multi-stage step-by-step lap joint process, and the lamination is a 45° oblique seam without hole binding structure. It not only reduces the no-load loss, but also greatly reduces the noise.

Transformer Winding:

The high, medium and low voltage winding are all wound on high-strength insulating cylinders. When winding, the wire tensioning device is used, and the unique climbing pad is used at the transposition, thus greatly enhancing the mechanical strength and short-circuit resistance of the winding.

Body Insulation:

The transformer body assembly and winding system are all completed in a fully enclosed constant temperature and constant pressure clean room, which meets the cleanliness requirements for manufacturing 500KV products and the constant temperature requirements of the body, further ensuring the cleanliness and dryness of the body. At the same time, kerosene vapor phase drying equipment is used to make the product cleanliness better.

Fuel Tank:

The fuel tank structure is bell type. The tank wall is welded with folded plate reinforced iron or plate reinforced iron, which improves the mechanical strength of the fuel tank. The sealing part of the fuel tank is specially processed, and the overall "sandblasting" treatment is carried out on the tank body to completely remove the oxide skin and processing on the surface of the tank body. The sharp corner burr welding slag produced in.

Components of Power Transformer

1.Core Components

The core supports the winding and provides a low reluctance path for the magnetic flux. It is made by stacking and laminating thin steel sheets. The sheets are insulated from each other by a coating. To reduce eddy current losses and hysteresis losses, the iron or steel sheets are less than one millimeter thick, and their carbon content is maintained below 0.1%. Eddy current is further reduced by alloying the steel with silicon. The vertical sections of the core in which the winding are carried are referred to as the limbs, while the horizontal sections of the core that couples the limbs are referred to as the yokes.

2.Winding in Power Transformers

The winding are made up of copper or aluminum conductor coil with a specific number of turns. Copper is the preferred material since it offers high electrical conductivity and high ductility; these properties reduce the amount of winding and make the material easier to wrap around the core.

A transformer consists of at least two winding the primary and the secondary winding. The primary winding is the winding in which the input voltage is applied, while the secondary winding is the winding that receives the output voltage. The primary and the secondary winding in a phase of a transformer can play as the high voltage (HV) winding or the low voltage (LV) winding:

HV Winding The HV winding has a greater number of turns and consists of a thinner conductor than the LV winding.

LV Winding The LV winding has a fewer number of turns. It consists of a thicker conductor than the HV winding since a higher current is carried in the LV winding.

3.Insulating Materials

Insulating materials are used to isolate the winding from the core, the primary and the secondary winding, and each turn of the winding. These materials protect the transformer from damage. Transformer insulators should have high dielectric strength, good mechanical properties, and can withstand high temperatures.

Paper and press-board can be used as an insulator (i.e., dry-type transformers); however, they have limited service lives and require frequent replacement as these materials can degrade. Hence, transformer oils are more common compared to solid insulating materials. They provide enhanced insulation between conducting parts, act as a coolant for the coil and winding assembly, and have fault detection features. Hydrocarbon mineral oils consisting of aromatics, paraffin, naphthalene, and ole-fins are used as transformer oils. Oil contamination must be prevented to preserve the oil's dielectric properties and insulating features

4.Tap Changer

Tap changers are devices that regulate the transformer’s output voltage as it responds accordingly to the varying input voltage and load by adjusting the number of turns in one winding. This adjustment, therefore, changes the turn ratio. During offloading conditions, the output voltage increases, whereas during loaded conditions, the output voltage decreases. Tap changers are typically connected in the HV winding to make fine voltage regulations and minimize core losses of the transformer. The current is also lower in the HV winding, which minimizes the risk of sparking and igniting the transformer oil.

There are two types of tap changers. On-load tap changers are designed to tap the voltage without disrupting the current flow to the load. Whereas offload tap changers require disconnecting the load of the transformer before operating.

5.Bushings in Transformers

Bushings are insulated barriers that contain the terminal that connects the current-carrying conductor from an electrical network to the ends of the transformer winding. The bushing insulation is typically made from porcelain or epoxy resin. The bushings are mounted over the main tank.

6.Transformer Tank

The transformer tank (or the main tank) houses and protects the core, winding, and other components from the external environment. It serves as the container for the transformer oil. It is constructed from rolled steel plates or aluminum sheets.

7.Conservator Component

The conservator is a tank that serves as the reservoir of the transformer oil and is located above the main tank and bushings. Transformer oil from the conservator is supplied to the main oil tank inside the transformer through a pipeline. The conservator has a flexible bladder that allows the expansion and contraction of the oil. It has an adequate space to allow the expansion of the oil during high ambient temperatures. The conservator is vented to the atmosphere to balance the pressure changes during the expansion and contraction of the oil by in-taking or releasing air.

8.Breather Component

The breather delivers moisture-free air to the conservator by passing air through a small bed of silica gel inside a cylindrical container. The silica gel acts as an air filter that strips and controls the moisture level inside the conservator and the main tank. The breather is connected by a pipeline to the conservator.

Moisture can degrade the insulating properties of the transformer oil or may even lead to internal faults. Therefore, it is necessary to remove the moisture.

9.Cooling System

The cooling system is a critical component of transformers regardless of the insulating material utilized. Power losses occurring in the transformers are in the form of heat increasing the temperature of the winding and the core. Consequently, the temperature of the insulating material will also increase. Without a cooling system, these components may be damaged or decomposed if heated continually. The cooling system of transformers consists of fans, radiators, and cooling tubes. Heat transfer mechanism occurs by natural and/or forced convection and radiation.

For dry-type transformers, cooling may be accomplished by the following methods:

1)Air Natural;2)Air Forced.

For oil-immersed type transformers, cooling may be accomplished by the following methods:

1)Oil Natural Air Natural;2)Oil Natural Air Forced;3)Oil Forced Air Forced;4)Oil Natural Water Forced;5)Oil Forced Water Forced.

10.Explosion Vent

The explosion vent is a metallic pipe with a diaphragm at its free end located slightly above the conservator tank. It releases gases, transformer oil, and energy during internal faults to relieve the excessive pressure inside the transformer, thus preventing the explosion of the transformer. Faults elevate the internal pressure of the transformer to dangerous levels. When such circumstances occur, energy will be released into the atmosphere, destroying the diaphragm at relatively low pressure.

11.Gas Relay

The Gas relay is a device installed along the pipeline connecting the conservator and the main tank. It detects faults in the transformer by sensing the emitted gases to activate the trip and alarm circuits. Once the trip circuit is activated, the circuit breaker will then disrupt the current flow to the primary winding. Emitted gases are generated by the heat released induced by faults.

Our Factory

Our factory covers an area of 33,300 square meters, with a total construction area of 6,100 square meters. There are currently 260 employees, including 18 technicians who have been engaged in the research and development of transformer products for many years, and 8 high-quality corporate managers. With the expansion of production scale and the increase of product varieties, it has now developed into a high-tech innovative enterprise that annual production capacity of more than 1000MVA, integrating the design, production and sales of open-type dry-type transformers, epoxy resin cast dry-type transformers, amorphous alloy transformers, and special transformers.

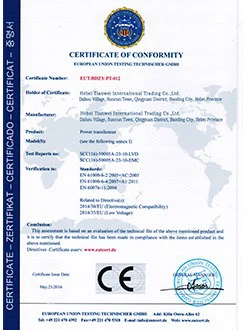

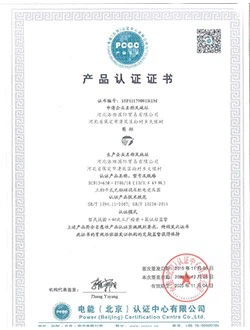

Our Certificate

Our company has passed the ISO9001-2008 international standard quality management system certification. All performance indicators of the products have reached the relevant national standards and international standards.

The oil immersed power transformers and dry-type transformers have passed the Test Report of the National Supervision and Inspection Center for Energy-saving Product Quality; Complete sets of low voltage switch-gear (GGD2) (GCK) has passed the test of China Compulsion Certification (CCC) from the State Bureau of Quality and Technical Supervision for Electrical Products; Indoor AC draw-out type metal clad switch-gear KYN28A-12 / 1250-31.5, fixed AC metal-enclosed Ring unit XGN15-12 / 1250-31.5 and XGN15 metal-enclosed switch-gears have passed the test of the National Quality Supervision and Inspection center for High-voltage Electrical Appliances Product.

FAQ

Q: Can you provide drawings and technical data?

Q: Have your products been exported?

Q: Can the products be manufactured by customer's requirement?

Q: Vi-sting factory is allowed or not?

Q: Do you looking for Agent?

Q: How to solve the equipment trouble during using ?

Q: What is a power transformer used for?

Q: What is the definition of a transformer in electricity?

Q: Where are power transformers used?

Q: What are the 5 applications of transformer?

Q: What are the components of 220kv substation?

Q: What is the safe distance for 220kV?

Q: What is the use of OLTC in transformer?

Q: What are the advantages of 3 winding transformer?

Q: What is three-phase three winding transformer?

Q: What is the purpose of oil in oil immersed transformer?

Q: What happens if a transformer is damaged?

Q: Why do power transformers fail?

Q: What causes a transformer to burn out?

Q: What should you do when a transformer is burning?

We're known as one of the most professional power transformer manufacturers and suppliers in China. Please rest assured to buy high quality power transformer for sale here from our factory. Good service and competitive price are available.

138kv transformer, 2000 mva transformer, large power transformer